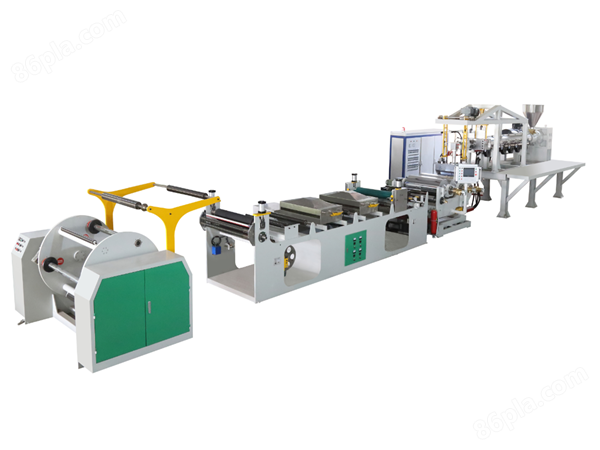

PET片材設備結構形式多樣,可歸納為傳統結晶干燥單螺桿、結晶排氣單螺桿,免結晶干燥排氣平行雙螺桿。無論何種結構形式,關鍵要點在于合理的螺桿結構才能生產出高品質的PET片材。本公司擁有從事PET行業二十多年豐富經驗,尤其在螺桿設計方面有突出業績的設計工程人員。泓泰機械PET片材機廠家所生產的PET片材機回料、壓力穩定、塑化好、產量高、能耗低,不飛車、不穿孔、無氣泡、不發脆等制品缺陷。

The structure of PET sheet equipment is diverse and can be summarized as traditional Crystal drying single screw, crystal exhaust single screw, nocrystalization Dry exhaust parallel twin screw. Regardless of the structure,The key point is the reasonable screw structure Ensure the production of high quality PET sheet. The company has over 20 years of experience in the PET industry, especially in screw design There are outstanding performance design engineers. The company's PET sheet machine can eat return material, stable pressure, good plasticization, high output, low energy consumption, no speed, no wear Holes, no bubbles, no brittle and other product defects.

技術參數Technical parameter | |||||

適用物料Applicable material | APET、PLA、植物淀粉( Plant starch ) | ||||

規格型號Speification model | HTJP90 | HTJP120 | HTJP120/65 | HTJP75S平雙 | HTJP95S平雙 |

產量(kg/h) Yield ( kg/h ) | 300 | 450 | 450 | 450 | 550 |

產品厚度誤差Product thickness eror | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

輥面寬度Rollwidth | 800~1000 | 800~1000 | 800~1600 | 800~1000 | 800~1600 |

裝機總功率Totalpower | ~280 | ~350 | ~550 | ~270 | ~320 |

設備外型尺寸Outer size | 視機型而定Depending on type and decide | ||||

聲明:由于產品技術不斷更新、完善、本章內容可能與實際產品不相符,不涉及到產品功能的更改,以實物為準!