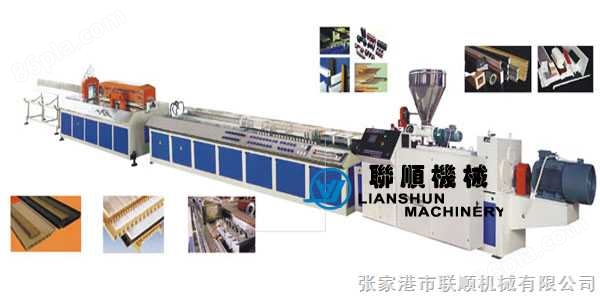

PVC塑窗異型材生產線

【簡單介紹】

【詳細說明】

PVC塑窗異型材生產線特點及用途: Features and application :

參照*,對機組進行優化設計,具有塑化均勻,剪切速率小,產量高,使用壽命長等優點。PVC塑窗異型材生產線有錐形雙螺桿擠出機、真空定型臺、牽引機、切割機、貼膜機、翻料架等組成。主機采用進口變頻調速,溫控儀表采用日本RKC產品。輔機真空泵和牽引電機均采用優質產品,維護簡便。也可直接擠出仿真木發泡異型材,效果比單螺桿更佳。塑鋼門窗異型材生產線配用錐雙擠出機,可加工PVC塑料門窗異型材、鋼塑復合異型材、異型電纜多孔穿線管、裝飾型材等。

It has referred to the latest foreign technology and has optimized the design. It has such advantages as even plastication, small shearing speed, high output, long life span, etc. This machine consists of cone double screw extruder, vacuum setting table, drawing machine, cutting machine, film sticking machine, material tumbling frame, etc. The main motor has applied imported inverter, temperature control apparatus are products of RKC of Japan. Auxiliary vacuum pump and drawing motor are all excellent quality products. It is simple to maintain. It may also directly extrude wood like balpo different shaped material, the effect is better than that of single screw extruder. If plasticated steel door & window different shaped material production line is used together with cone double screw extruder, it may process PVC plastic door & window different shaped material, steel-plastic compound different shaped material, different shaped multi-hole tubes for cables, shaped material for decoration, etc.

MSN交談

MSN交談