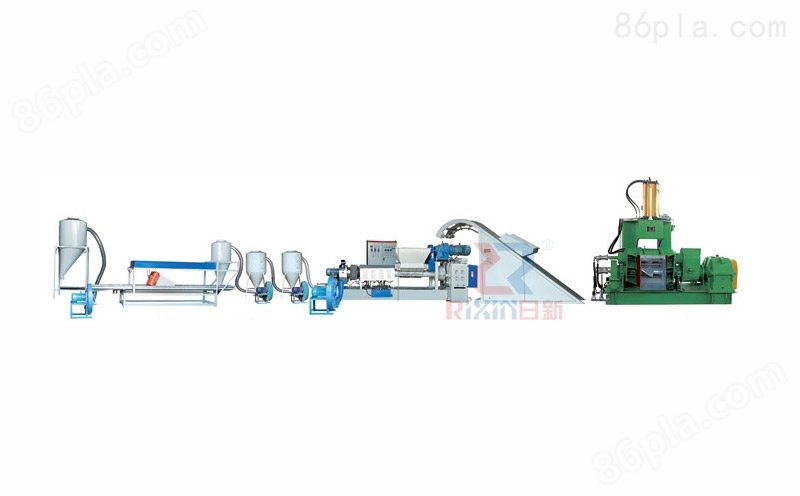

色母粒造粒機

色母粒高速造粒整廠設備特點:1.色母粒高速造粒整廠設備集混煉、輸送、喂料、擠出造料,風送熱切冷卻于一體,實現自動化連續作業,生產效率高。

2.PE色母造粒機設備結構緊湊,占地及空間小,可以平面安裝。

3.生產過程進行分段閉環溫度控制,密煉、喂料、擠出機等有各自加熱、冷卻系統,根據工藝要求控制各自溫度。

4.喂料機構采用螺旋槳雙挽式,吃料能力強。特別適用于直接經密煉機混煉的團狀物料擠出造粒。

5.機筒螺桿均采用38CrMoAIA優質合金鋼,經氮化處理,硬度高,耐磨耐腐蝕。

6.機頭采用手動換網或快速不停機換網機構,提高生產效率。

7.電控系統采用*的PLC控制技術,與多臺變頻器組成,使喂料、擠出、切料等多機臺按工藝要求進行高精度、廣范圍的無極調速。并具有全機工藝連鎖,聲光故障報警等功能控制,完善可靠。

High filling,high densive black-white master granule,functional master granule ,color master granule,film master granule high-oelletizing whole plant equipments

Features:

1.The production line is composed of mixing mill,bucket conveyor,feeder,extruder,palletizer with heat-cut methods,featuring high automation and capacity .It is characterized by compact construction.

2.The machine occupies less space and floor area and is installed in foundation.

3.The kneader,feeder and extruder of the pelletizing machine have their own heating and cooling systems respectively,which can perform closed-circuit temptrature control themselves according to the requirement of special technology in producing.

4.Feeding mechanism is of tapered twin screws in desing and has a strong feeding capacity. It is specially used for mining materials dirctly through the mixer to extrude in pelletizing.

5.Cylinder and extruder screw made of high-quality alloy steel-380CrMoAIA are treated with nitrogen fixation,featuring high hardness,wear-resistant and corrosion.

6.An automatic or manual screen changer between the extrusion screw and head can higher efficiency in the replacement of the screes while the line is running without stop.

7.Electrical system with PLC contorl technique composed of transformers make the feeder and extruder,pelletining machine work with high precision according to the technological requirement in great range of stepless speed regulation. The line can interlock,alarm with light and voice,It can do it reliably and perfectly.