注塑機(jī) 擠出機(jī) 造粒機(jī) 吹膜機(jī) 吹塑機(jī) 吹瓶機(jī) 成型機(jī) 吸塑機(jī) 滾塑機(jī) 管材生產(chǎn)線 板材生產(chǎn)線 型材生產(chǎn)線 片材生產(chǎn)線 發(fā)泡設(shè)備 塑料壓延機(jī)

四川川大干燥科技工程有限責(zé)任公司

會(huì)員1.png)

四川川大干燥科技工程有限責(zé)任公司

會(huì)員1.png)

| 參 考 價(jià) | 面議 |

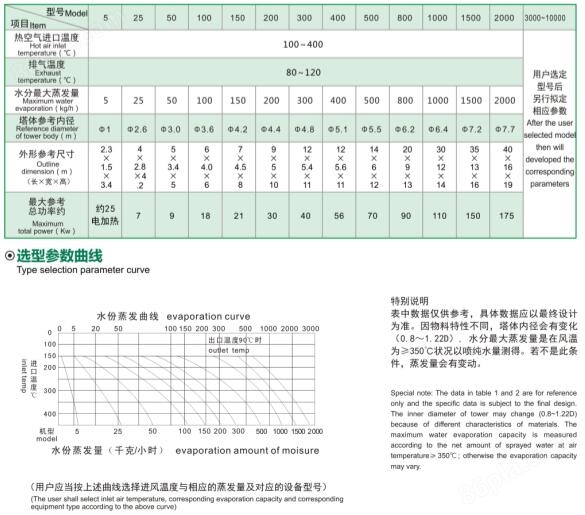

產(chǎn)品型號(hào)

品 牌

廠商性質(zhì)其他

所 在 地成都市

塑料機(jī)械網(wǎng)采購(gòu)部電話:0571-88918531 QQ:2568841715

QQ:2568841715

聯(lián)系方式:查看聯(lián)系方式

更新時(shí)間:2023-07-27 09:32:06瀏覽次數(shù):397次

聯(lián)系我時(shí),請(qǐng)告知來(lái)自 塑料機(jī)械網(wǎng)暫無(wú)信息 |

一、工作原理及應(yīng)用范圍介紹IntroductionofWorkingPrincipleandScopeofApplication物料經(jīng)高速旋轉(zhuǎn)離心盤(pán)的作用形成微細(xì)霧滴與并(逆)流熱風(fēng)接觸從而達(dá)到快速干燥之目的

物料經(jīng)高速旋轉(zhuǎn)離心盤(pán)的作用形成微細(xì)霧滴與并(逆)流熱風(fēng)接觸從而達(dá)到快速干燥之目的。主要應(yīng)用于將粘性溶液中的固含物快速脫除溶劑而獲得粉狀或微細(xì)顆粒狀物料的過(guò)程裝備。特別適用于熱敏性物料的噴霧快速脫水干燥,如奶粉,植物提取液,生物、化工、化學(xué)合成溶液,血液制品,蛋白粉等。本系統(tǒng)廣泛應(yīng)用于醫(yī)藥、食品、化工、飼料、生物工程、冶金、環(huán)保等領(lǐng)域。高速?lài)婌F干燥機(jī)

The materials are processed into fine droplets by the high-speed rotating centrifugal disk and then contacted with the hot air of parallel (reverse) flow for purpose of rapid drying. The unit is mainly used for the process equipment that produces powdery or fine granular materials after rapid solvent removal for the solid materials in viscous solutions, and is particularly applicable to the rapid dewatering and drying for the spray of heat sensitive materials, e.g. milk powder, plant extracts, organisms, chemical industry, chemical synthetic solutions, blood products, albumen powder, etc. This system is widely applied in these fields such as medicine, food, chemical industry, feed, bioengineering, metallurgy and environmental protection, etc.

1.噴干出來(lái)的產(chǎn)品粒徑小、堆密度小、產(chǎn)品呈粉狀。

2.進(jìn)風(fēng)溫度可任意調(diào)節(jié)以滿足工藝需求,對(duì)料液的粘度適應(yīng)范圍廣。

3.整個(gè)烘干脫水過(guò)程時(shí)間短(最多30秒內(nèi)完成),熱敏破壞作用小,氧化破壞作用小,能充分保持物料本身的色、香、味等。

4.烘干出來(lái)的產(chǎn)品分散性、流動(dòng)性、溶解性很好。

5.根據(jù)工況及用戶需求可實(shí)現(xiàn)全程自動(dòng)化、智能化、無(wú)塵化、無(wú)菌化、自動(dòng)清洗操作、自動(dòng)記錄、貯存、打印需求。

1.The spray-dried products are powdery with a small particle size and small bulk density.

2.The inlet air temperature can be adjusted arbitrarily to meet process requirements and is applicable to a wide scope of viscosities of feed liquid.

3.The entire drying and dehydration process is short (it will be completed in a maximum period of up to 30s). The heat sensitive and oxidative destructive effects are small, thus the color, fragrance, flavor, etc. of materials can be fully maintained.

4.The spray-dried products have good dispersity, mobility and solubleness.

5.Full automatic, intelligent, dust-free, aseptic and self-cleaning operations, automatic recording, storage, and printing requirements can be achieved depending on the working conditions and user demands.

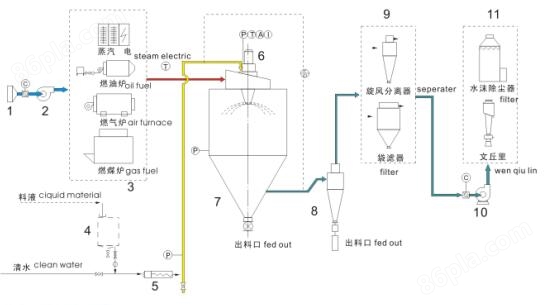

四、工藝流程圖Process flow diagram

您感興趣的產(chǎn)品PRODUCTS YOU ARE INTERESTED IN

塑料機(jī)械網(wǎng) 設(shè)計(jì)制作,未經(jīng)允許翻錄必究 .? ? ?

請(qǐng)輸入賬號(hào)

請(qǐng)輸入密碼

請(qǐng)輸驗(yàn)證碼

請(qǐng)輸入你感興趣的產(chǎn)品

請(qǐng)簡(jiǎn)單描述您的需求

請(qǐng)選擇省份

聯(lián)系方式

四川川大干燥科技工程有限責(zé)任公司