注塑機 擠出機 造粒機 吹膜機 吹塑機 吹瓶機 成型機 吸塑機 滾塑機 管材生產線 板材生產線 型材生產線 片材生產線 發泡設備 塑料壓延機

杭州星標機械有限公司

杭州星標機械有限公司

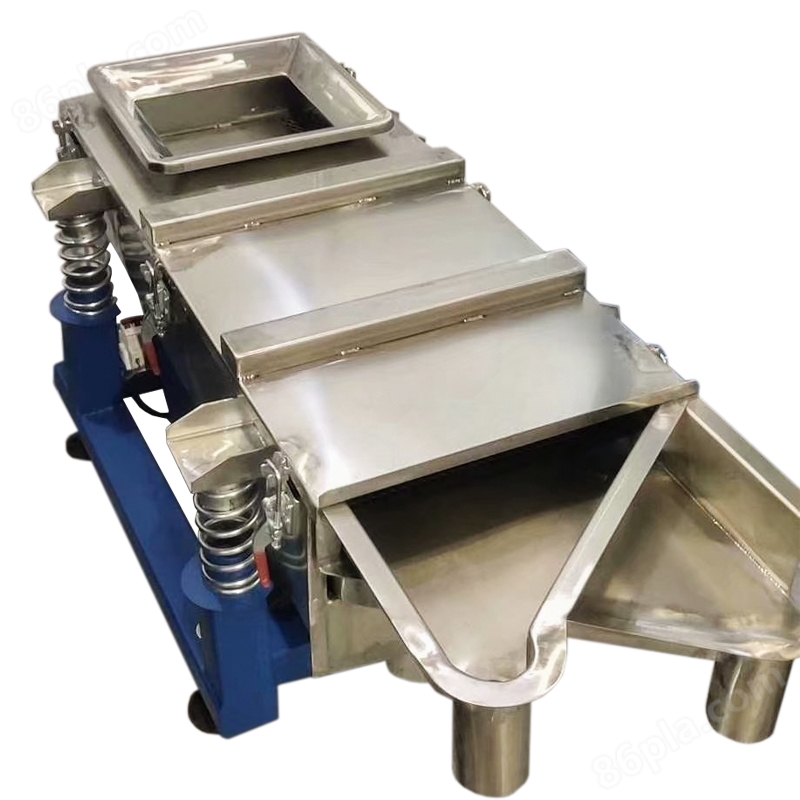

振動篩采用雙振動電機驅動,當兩臺振動電機做同步、反缶旋轉時,其偏心塊所產生的激振力在平行于電機軸線的方向相互抵消,在垂直于電機軸的方向疊為一協力,因此篩機的運動軌跡為一直線

振動篩采用雙振動電機驅動,當兩臺振動電機做同步、反缶旋轉時,其偏心塊所產生的激振力在平行于電機軸線的方向相互抵消,在垂直于電機軸的方向疊為一協力,因此篩機的運動軌跡為一直線。其兩電機軸相對篩面有一傾角,在激振力和物料自重力的協力作用下,物料在篩面上被拋起跳躍式向前作直線運動,從而達到對物料進行篩選和分級的目的。可用于流水線中實現自動化功課。具有能耗低、效率高、結構簡樸、易維修、全結構無粉塵溢散的特點,篩分目數325目,可篩分出7種不同粒度的物料。

Vibrating screen with double vibration motor drive, when the two vibration motors do synchronous, anti fv rotation, the eccentric block produced by the vibration force in parallel to the direction of the axis of the motor offset each other, in the direction perpendicular to the axis of the motor stacked for a concerted effort, so the motion track of the screen machine is a straight line. The two motor shafts relative to the screen surface has a dip Angle, in the excitation force and material since the gravitational force of the cooperative action, the material on the screen surface was thrown up jump forward for linear motion, so as to achieve the purpose of screening and classification of materials. Can be used to achieve automatic work in the pipeline. It has the characteristics of low energy consumption, high efficiency, simple structure, easy maintenance, complete blocking structure without dust overflow and dispersion, the highest screening mesh number of 325 mesh, can screen out 7 kinds of materials of different particle size.

主要由篩箱、篩框、篩網、振動電機、電機臺座、減振彈簧、支架組成。

1. 篩箱:由數張厚度不同的鋼板焊制而成,具有一定的強度和剛度,是篩機的主要組成部分。

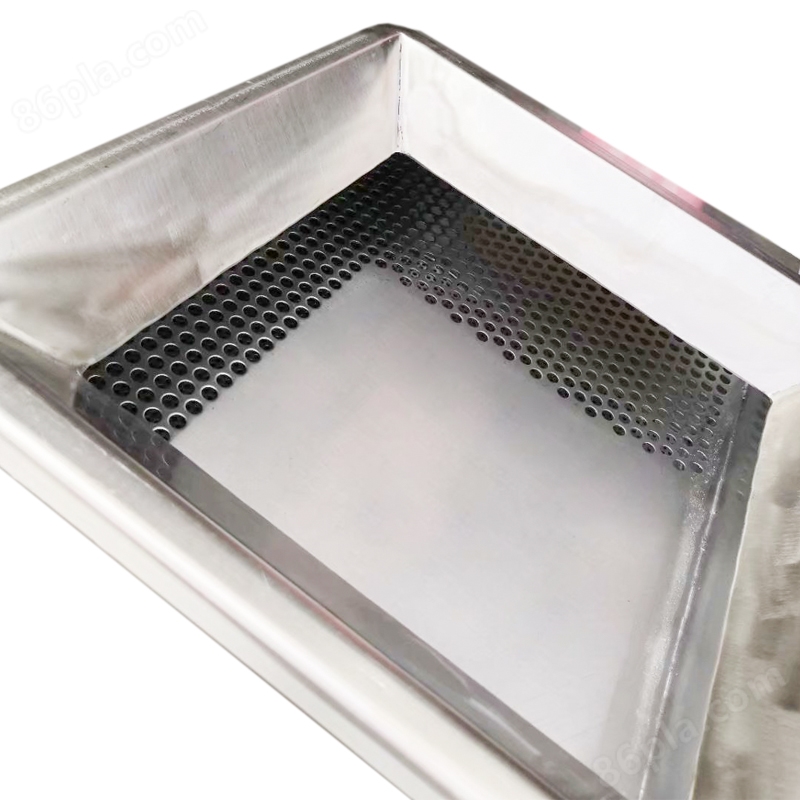

2. 篩框:由三角鐵制成,主要用來保持篩網平整,達到正常篩分。

3. 篩網:有低碳鋼、黃銅、青銅、不銹鋼絲等多種篩網。

4. 振動電機

5. 電機臺座:下振式(電機安裝在篩箱下方的)篩機的電機臺座是可以移動的,使用前連接螺釘必須擰緊,特別是新篩機試用前三天必須反復緊固,以免松動造成事故。

6. 減振彈簧:阻止振動傳給地面同時支持篩箱的全部重量。安裝時,彈簧必須垂直于地面。

7. 支架:由四個支柱和兩個槽鋼組成,支撐著篩箱。安裝時支柱必須垂直于地面,兩支柱下面的槽鋼應相互平行。

Linear vibrating screen is composed of which parts:

It is mainly composed of screen box, screen frame, screen mesh, vibration motor, motor pedicle, vibration spring and bracket.

1. Screen box: welded by several steel plates of different thickness, with a certain strength and stiffness, is the main component of the screen machine.

2. Screen frame: made of triangular iron, mainly used to keep the screen smooth, to reach the normal screening.

3. Screen: low carbon steel, brass, bronze, stainless steel wire and other kinds of screen.

4. Vibration motor

5. Motor pedestal: the motor pedestal of the vibration type (motor installed under the screen box) sieve machine can be moved, and the connecting screw must be tightened before use, especially the three days before the trial of the new screen machine must be tightened repeatedly, so as not to loose and cause accidents.

6. Damper spring: prevent vibration to the ground and support the full weight of the screen box. Spring must be perpendicular to the ground when installed.

7. Support: It is composed of four pillars and two channels to support the screen box. The pillars must be perpendicular to the ground during installation, and the channel steel under the two pillars should be parallel to each other.

直線震動篩參數

型號 | 單電機 | 雙電機 |

電機功率(kw) | 0.12 | 0.12*2個 |

外形尺寸(mm) | 1300*600*640 | 1500*750*640 |

網孔尺寸(mm) | 940*370 | 1170*530 |

網孔2層及大小(mm) | 上層8mm、下層2mm | 上層8mm、下層2mm |

進料粒度< | 8mm | 8mm |

塑料顆粒產量 | 250kg/h | 250kg/h |

材質 | 201不銹鋼 | 201不銹鋼 |

您感興趣的產品PRODUCTS YOU ARE INTERESTED IN

塑料機械網 設計制作,未經允許翻錄必究 .? ? ?

請輸入賬號

請輸入密碼

請輸驗證碼

請輸入你感興趣的產品

請簡單描述您的需求

請選擇省份