注塑機(jī) 擠出機(jī) 造粒機(jī) 吹膜機(jī) 吹塑機(jī) 吹瓶機(jī) 成型機(jī) 吸塑機(jī) 滾塑機(jī) 管材生產(chǎn)線 板材生產(chǎn)線 型材生產(chǎn)線 片材生產(chǎn)線 發(fā)泡設(shè)備 塑料壓延機(jī)

張家港市億春機(jī)械制造有限公司

會(huì)員1.png)

行業(yè)產(chǎn)品

張家港市億春機(jī)械制造有限公司

會(huì)員1.png)

| 參 考 價(jià) | 面議 |

產(chǎn)品型號(hào)

品 牌

廠商性質(zhì)其他

所 在 地張家港市

塑料機(jī)械網(wǎng)采購部電話:0571-88918531 QQ:2568841715

QQ:2568841715

聯(lián)系方式:查看聯(lián)系方式

更新時(shí)間:2023-06-28 14:21:45瀏覽次數(shù):442次

聯(lián)系我時(shí),請(qǐng)告知來自 塑料機(jī)械網(wǎng)PVC穿線管生產(chǎn)線

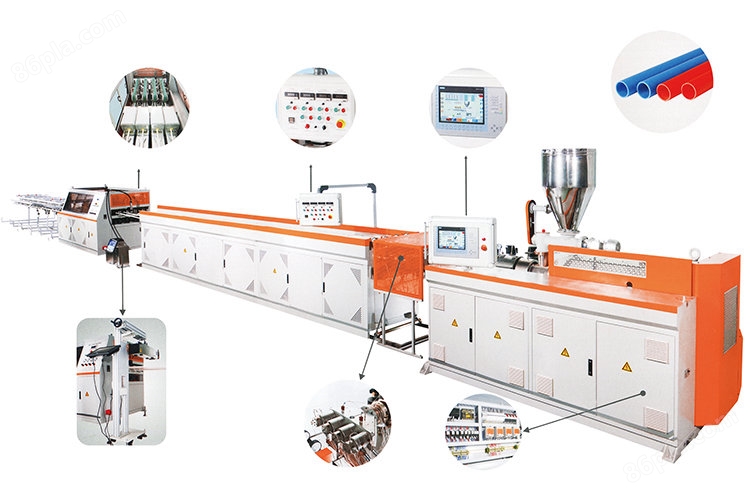

PVC穿線管生產(chǎn)線

PVC threaded pipe production line

連體牽引切割機(jī):繁湊小巧

Haul off & cutter unit: compact

美國(guó)原裝控制箱

American original control box

德國(guó)西門子可編輯邏輯控制器

Germany Siemens PLC

無油墨印字機(jī)

Ink-free printer

模具:采用加工中心制造

Processed by CNC

電器組件

Imported electrical components

主要技術(shù)參數(shù)/Main technical parameters

型號(hào)Model | KBLF-32-Ⅰ | KBLF-32-Ⅱ |

螺桿直徑(mm) Screw diameter | 65/132 | 80/156 |

螺桿數(shù)量(pcs) quantity of Screw | 2 | 2 |

螺桿轉(zhuǎn)向Screw direction | 異向向外Opposite outward rotation | 異向向外Opposite outward rotation |

螺桿轉(zhuǎn)速(r/min) Soeed of screw rotation | 1-36 | 1-35 |

螺桿有效長(zhǎng)度(mm) Effective length of screw | 1430 | 2080 |

結(jié)構(gòu)形式Structure of screw | 錐形齒合 Conical mesh | 錐形齒合 Conical mesh |

主電機(jī)功率(kw) Motor power | 37 | 55 |

總功率(kw) Total power | 100 | 135 |

擠出量(kg/h) Max. capacity | 250-300 | 350-450 |

機(jī)筒加熱段數(shù)(pcs) Quantity of barrel heating | 4 | 4 |

加熱方式Heating method | 鑄鋁加熱 Cast aluminum heating + Ceramic heating | 鑄鋁加熱 Cast aluminum heating + Ceramic heating |

主機(jī)中心高(mm) Center neight | 1000 | 1000 |

整機(jī)重量(kg) Weight | 3200 | 4500 |

外形尺寸(mm) Dimension(L×W×H) | 4500×1500×2400 | 5500×1550×2400 |

生產(chǎn)線特點(diǎn)和功能

一出四PVC管材生產(chǎn)線即一模生產(chǎn)四條線管,在保證產(chǎn)品質(zhì)量的前提下,改設(shè)備降低了設(shè)備投入成本、廠房投入成本和生產(chǎn)投入成本,大大提高產(chǎn)量,減少生產(chǎn)時(shí)間。

生產(chǎn)范圍:生產(chǎn)管材直徑的范圍為16mm-32mm

裝機(jī)總功率:在80KW左右

生產(chǎn)能力:一出四管材生產(chǎn)線在保持一出二管材生產(chǎn)線產(chǎn)品質(zhì)量的前提下,產(chǎn)量提高了約60%-70%

電力損耗:平均每噸只需80-90KW電耗

噪音總量:生產(chǎn)線正常啟動(dòng)后,基本無噪音

粉塵污染:一出四管材生產(chǎn)線切割部分為無屑切割,整條生產(chǎn)線基本無粉塵污染

PVC four pipes extrusion line has its advantages of high production capacity. Comparing with the common

extrusion line, PVC four pipes extrusion line has less investment at equipment cost, factory investment and

production investment. PVC four pipes extrusion line has high capacity with less production consumption

Production pipe range: Most suitable pipe range is 76-32MM

Total installation power: About 80kw

Production capacity: Comparing with the capacity of common PVC two pipes extrusion line, PVC four pipes extrusion line has more 60%-700% capacity.

Power consumption: Only 80-90kw per ton averagely

Noise: Less noise during normal production

Dust pollution: There is no dust pollution from this extrusion line, as the cutter is chipless cutter

您感興趣的產(chǎn)品PRODUCTS YOU ARE INTERESTED IN

塑料機(jī)械網(wǎng) 設(shè)計(jì)制作,未經(jīng)允許翻錄必究 .? ? ?

請(qǐng)輸入賬號(hào)

請(qǐng)輸入密碼

請(qǐng)輸驗(yàn)證碼

請(qǐng)輸入你感興趣的產(chǎn)品

請(qǐng)簡(jiǎn)單描述您的需求

請(qǐng)選擇省份

聯(lián)系方式

張家港市億春機(jī)械制造有限公司