注塑機(jī) 擠出機(jī) 造粒機(jī) 吹膜機(jī) 吹塑機(jī) 吹瓶機(jī) 成型機(jī) 吸塑機(jī) 滾塑機(jī) 管材生產(chǎn)線 板材生產(chǎn)線 型材生產(chǎn)線 片材生產(chǎn)線 發(fā)泡設(shè)備 塑料壓延機(jī)

臺州屹捷數(shù)控機(jī)床股份有限公司

會員1.png)

臺州屹捷數(shù)控機(jī)床股份有限公司

會員1.png)

| 參 考 價(jià) | 面議 |

產(chǎn)品型號YJ-CK220ST

品 牌

廠商性質(zhì)其他

所 在 地臺州市

塑料機(jī)械網(wǎng)采購部電話:0571-88918531 QQ:2568841715

QQ:2568841715

聯(lián)系方式:查看聯(lián)系方式

更新時(shí)間:2023-05-24 18:09:31瀏覽次數(shù):308次

聯(lián)系我時(shí),請告知來自 塑料機(jī)械網(wǎng)YJ-CK220ST雙頭雙刀塔數(shù)控車床軸類零件需要加工兩端的端面時(shí),通常是先加工零件的一頭然后調(diào)頭加工另一頭,這樣做法是經(jīng)過了兩次裝夾加工,同軸度精度得不到很好的控制,同時(shí)對工人操作技術(shù)要求高。

YJ-CK220ST雙頭雙刀塔數(shù)控車床性能特點(diǎn):

產(chǎn)品性能:

軸類零件需要加工兩端的端面時(shí),通常是先加工零件的一頭然后調(diào)頭加工另一頭,這樣做法是經(jīng)過了兩次裝夾加工,同軸度精度得不到很好的控制,同時(shí)對工人操作技術(shù)要求高。

本項(xiàng)目改變傳統(tǒng)機(jī)床加工單頭加工方式,采用一次裝夾、兩端同時(shí)加工的方式,研制一種加工精度高、效率高、廢品率低、減輕工人操作強(qiáng)度的單主軸雙面雙刀塔數(shù)控機(jī)床。

特點(diǎn):

(1)、雙面復(fù)合加工技術(shù)設(shè)計(jì)

利用兩組刀塔,一次性裝夾、完成零件兩端的多工位加工方法,將原先需要在若干個(gè)工步中去除的加工余量集中在一個(gè)復(fù)合的工步中,使多個(gè)工步的加工時(shí)間全部重合,且一次裝夾完成兩端的加工,避免多次裝夾而產(chǎn)生的誤差,保證加工精度,減少加工輔助時(shí)間,效率提升2-4倍。

(2)、兩端雙卡盤主軸箱設(shè)計(jì)

采用主軸箱雙卡盤中間兩端對稱夾裝方式,改變傳統(tǒng)軸類零件單向不對稱夾裝在切屑過程中受迫振動,導(dǎo)致零件表面質(zhì)量、尺寸及位置精度到不到要求問題。同時(shí)主軸箱兩端卡盤之間設(shè)有讓位槽,能對軸類中部具有異性結(jié)構(gòu)的零件進(jìn)行夾裝,擴(kuò)大了機(jī)床加工的通用性。

(3)可延雙向主軸設(shè)計(jì)

采用一種可延長的雙向主軸,設(shè)計(jì)有殼套組件、兩個(gè)可拆卸的固定于殼套組件兩端的延長套以及嵌設(shè)于延長套用于夾持工件的卡套,殼套組件上設(shè)置有驅(qū)使其中一個(gè)延長套沿軸向移動的控制結(jié)構(gòu);通過控制結(jié)構(gòu)實(shí)現(xiàn)卡套軸向延伸的目的,具有可在僅僅更換部分零件的狀況下完成雙向主軸的可夾持的規(guī)格的變化,大大減少主軸的更換成本和維修成本,并有效的提高了主軸的適用范圍的優(yōu)點(diǎn)。

(4)、智能化控制系統(tǒng)設(shè)計(jì)

本項(xiàng)目設(shè)計(jì)一套共用主軸箱傳動控制系統(tǒng)和2套左右對稱的結(jié)構(gòu)刀塔傳動運(yùn)行控制系統(tǒng),通過用PLC控制設(shè)計(jì),取代部分繼電器,對電路進(jìn)行改造設(shè)計(jì),實(shí)現(xiàn)對機(jī)床的智能化控制,提高接觸穩(wěn)定性,同時(shí)減少布線,提高生產(chǎn)效率。

1. product performance:

When the shaft parts need to be machined at both ends, it is usually first to process one part of the part and then to process the other head. This way is two times of clamping, and the precision of the coaxiality is not well controlled. At the same time, the technical requirements of the workers are high.

This project changes the traditional machine tool processing single head processing mode, using the one clamping and both ends processing at the same time, to develop a single spindle double-sided double knife tower CNC machine tool with high processing precision, high efficiency, low scrap rate and reduce the operation strength of the workers.

2. characteristics:

(1) and double side compound machining technology design

Using two sets of knife towers, the processing method of multi position machining at both ends of the parts is installed at one time. The processing allowance which is originally needed to be removed in several steps is concentrated in a compound work step, so that the processing time of the multiple steps is all recombined, and the addition of the two ends is completed at one time to avoid the error caused by multiple clamping. It can ensure machining accuracy, reduce processing auxiliary time and increase efficiency by 2-4 times.

(2) design of special spindle box for two ends double card disk

The symmetrical clamping method of the two ends of the spindle box is used to change the forced vibration of the unsymmetric clamping of the traditional axis parts in the chip process, which leads to the problem of the surface quality, size and position accuracy. At the same time, the chuck between the two ends of the spindle box is equipped with a slot to clamp the parts with different structures in the middle part of the shaft, thus enlarging the versatility of the machine tool processing.

(3) design of deferred bi-directional spindle

An extended bi-directional spindle is used to design a shell sleeve component, two detachable extended sleeves fixed at both ends of the shell assembly and a clamping sleeve embedded in the lengthening sleeve for holding the workpiece. A control structure is arranged on the sleeve component to drive one of the extended sleeves along the axis, and the axial extension of the sleeve is realized through the control structure. The purpose of extension is that the change of the clamped specification of the bi-directional spindle can be completed in the condition of only replacing part of the parts, which greatly reduces the replacement cost and maintenance cost of the spindle, and effectively improves the advantages of the application range of the spindle.

(4) design of intelligent control system

This project is designed to share the main shaft box transmission control system and 2 sets of symmetrical structure tool tower transmission control system. By using PLC control design to replace partial relay and redesign the circuit, realize the intelligent control of the machine tool, improve the contact stability, reduce the wiring and improve the production efficiency.

YJ-CK220ST雙頭雙刀塔數(shù)控車床技術(shù)參數(shù):

| 機(jī)床型號 | YJ-CK220ST |

| 大工件長度mm | 2500 |

| 主軸通孔直徑mm | φ80-220 |

| 主軸轉(zhuǎn)速范圍rpm | 100-1000 |

| 主軸轉(zhuǎn)速級數(shù) | 無級變速 |

| X軸大行程mm | 400 |

| Z軸大行程mm | 2500 |

| X軸大移動速度mm | 20000 |

| Z軸大移動速度mm | 24000 |

| X軸小設(shè)定單位mm | 0.001 |

| Z軸小設(shè)定單位mm | 0.001 |

| 主電機(jī)功率KW | 11KW/13KW |

| 主軸夾緊方式 | 液壓 |

| 刀架形式 | 刀塔 |

| 刀方尺寸mm*mm | 25*25 |

| 導(dǎo)軌形式 | 滾柱線軌 |

| 床身形式 | 30° |

| 機(jī)床外形尺寸mm | 5300*2200*2000 |

| 機(jī)床凈重kg | 9500 |

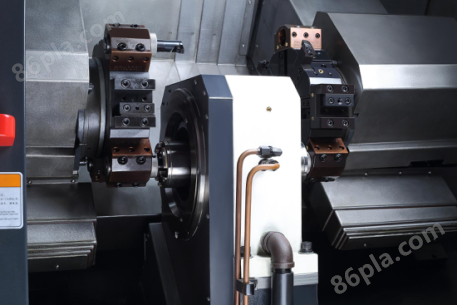

機(jī)床圖片:

細(xì)節(jié)圖片:

YJ-CK130ST雙頭雙刀塔數(shù)控車

您感興趣的產(chǎn)品PRODUCTS YOU ARE INTERESTED IN

主營產(chǎn)品:數(shù)控車床,雙頭車庫,加工中心,數(shù)控車銑床,雙主軸雙刀塔自動車床,斜軌數(shù)控車床,車銑中心,立式加工中心,數(shù)控系統(tǒng),機(jī)床附件

塑料機(jī)械網(wǎng) 設(shè)計(jì)制作,未經(jīng)允許翻錄必究 .? ? ?

請輸入賬號

請輸入密碼

請輸驗(yàn)證碼

請輸入你感興趣的產(chǎn)品

請簡單描述您的需求

請選擇省份

聯(lián)系方式

臺州屹捷數(shù)控機(jī)床股份有限公司