產品展示

【簡單介紹】

【詳細說明】

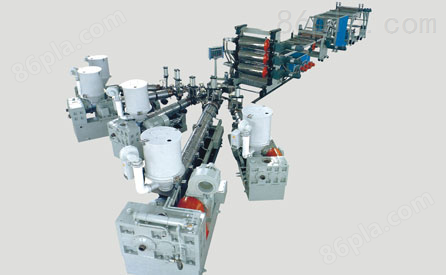

多層片材擠出機生產線

單層多層片材擠出機PC、PP、PE、PS、EVA、ABS片材押出機 PC、PP、PE、PS、EVA、ABS plastic sheet extruder1. 螺桿采用特殊混料功能及高塑化能力設計,確保膠料的塑化良好及穩定的高產量押出.2.衣架型模頭采用特殊雙節流設計,使板材厚薄調整更為精準。可選配多種形式的液壓單向換網器,雙向換網器;及不停機雙流道換網器。并可通過配直高效靜態混合器,熔體輸出計量泵,確保物料平穩押出。3.三輥壓光機采用水平垂直或45°傾斜式.可自由調節升降方式。間隙調整便捷,確保壓光效果。4.組合式獨立輥筒溫控系統能有效精確控溫,確保厚薄均勻.收卷裝置采用高扭矩馬達.能隨意調整速度及張力.配合分條及自動計速裝置可精確設定所需產制品寬度及長度。1.Extruder: Specially designed for high compounding and plasticization capacity so as to ensure high and stable extruding output.2.Clothes-rack style extruding die adopts double-channel design that ensure the thickness of sheet can be adjusted precisely. All kinds of screen changer are available such as single screen, bidirectional screen changer as well non-stop double-channel screen changer. High-effect static mixer and flow meter ensure stable extruding. 3.Three roller calendar adopts horizontal , 45°inclined or vertical type according to material property. The clearance among rollers can be adjusted freely so ensure calendaring effect.4.Combined separate roller temperature controlling system can precisely adjust temperature so as to keep even thickness.Winder device adopts powerful torque motor that freely adjusts speed and tension. Slit unit and automatic speed controller can precisely set the width and length of product.