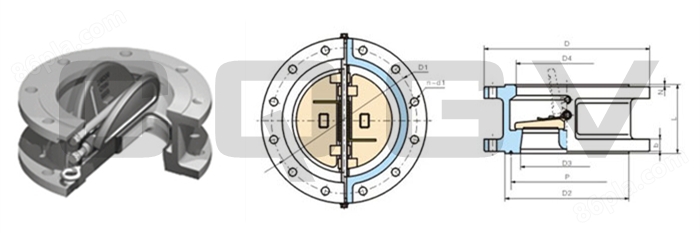

法蘭雙瓣旋啟式止回閥產品概述

法蘭雙瓣旋啟式止回閥又稱為逆流閥、逆止閥、背壓閥、單向閥。這類閥門是靠管路中介質本身的流動產生的力而自動開啟和關閉的,屬于一種自動閥門。止回閥用于管路系統,其主要作用是防止介質倒流、以及容器內介質的泄放。止回閥還可用于給其中的壓力可能升至超過主系統壓力的輔助系統提供補給的管路上。

法蘭雙瓣旋啟式止回閥產品特點

1、適用于垂直或水平管道,安裝方便;

2、流道暢通,流體阻力小;

3、動作靈活,密封性能好;

4、閥門行程窄,關閉沖擊小;

5、整體結構,簡單緊湊,外形美觀;

6、使用壽命長,可靠性好。

法蘭雙瓣旋啟式止回閥執行標準

| 產品規范 Product specification | 設計與制造 Design manufacture | 結構長度 Structure length | 壓力-溫度 Pressure temperature | 法蘭尺寸 Flange size | 檢驗與實驗 Inspection experiment |

| API 6D API 594 | ANSI B16.10 API 6D | ANSI B16.34 | ANSI B16.5 | API1598 API 6D |

法蘭雙瓣旋啟式止回閥結構尺寸

| 磅級 Class | 規格 Size | 尺寸 Dimension | |||||||||

| DN | NPS | L | D | D1 | D2 | D3 | D4 | b | f | Z-d0 | |

| 150LB | 50 | 2 | 60 | 152 | 120.5 | 92 | 51 | 56 | 16 | 1.6 | 4-19 |

| 65 | 2-1/2 | 67 | 178 | 139.7 | 105 | 65 | 73 | 18 | 1.6 | 4-19 | |

| 80 | 3 | 73 | 190 | 152.5 | 127 | 80 | 88 | 19 | 1.6 | 4-19 | |

| 100 | 4 | 73 | 229 | 190.5 | 157 | 102 | 108 | 24 | 1.6 | 8-19 | |

| 125 | 5 | 86 | 254 | 215.9 | 186 | 127 | 132 | 24 | 1.6 | 8-22 | |

| 150 | 6 | 98 | 279 | 241.5 | 261 | 152 | 160 | 26 | 1.6 | 8-22 | |

| 200 | 8 | 127 | 343 | 298.5 | 270 | 203 | 210 | 29 | 1.6 | 8-22 | |

| 250 | 10 | 146 | 406 | 362 | 324 | 254 | 266 | 31 | 1.6 | 12-25 | |

| 300 | 12 | 181 | 483 | 431.8 | 381 | 305 | 310 | 31.8 | 1.6 | 12-25 | |

| 350 | 14 | 184 | 533 | 476.2 | 412.8 | 350 | 355 | 35 | 1.6 | 12-28.5 | |

| 400 | 16 | 191 | 597 | 539.8 | 469.9 | 400 | 405 | 36.6 | 1.6 | 16-28.5 | |

| 450 | 18 | 203 | 635 | 577 | 533.4 | 450 | 455 | 39.7 | 1.6 | 16-31.8 | |

| 500 | 20 | 219 | 589 | 635 | 584.2 | 500 | 505 | 42.9 | 1.6 | 20-31.8 | |

| 600 | 24 | 222 | 813 | 749.3 | 692.2 | 600 | 605 | 47.7 | 1.6 | 20-35 | |

| 300LB | 50 | 2 | 60 | 165 | 127 | 92 | 51 | 58 | 22 | 1.6 | 8-19 |

| 65 | 2-1/2 | 67 | 190 | 149 | 105 | 65 | 73 | 25 | 1.6 | 8-22 | |

| 80 | 3 | 73 | 210 | 168 | 170 | 80 | 88 | 29 | 1.6 | 8-22 | |

| 100 | 4 | 73 | 254 | 200 | 157 | 102 | 108 | 32 | 1.6 | 8-22 | |

| 125 | 5 | 86 | 279 | 235 | 186 | 127 | 132 | 35 | 1.6 | 8-22 | |

| 150 | 6 | 98 | 318 | 270 | 216 | 152 | 160 | 37 | 1.6 | 12-22 | |

| 200 | 8 | 127 | 381 | 330 | 270 | 203 | 210 | 41 | 1.6 | 12-25 | |

| 250 | 10 | 146 | 444 | 387.4 | 324 | 254 | 266 | 47.6 | 1.6 | 16-28.5 | |

| 300 | 12 | 181 | 521 | 450.8 | 381 | 305 | 310 | 50.8 | 1.6 | 16-31.8 | |

| 350 | 14 | 222 | 584 | 514.4 | 412.8 | 350 | 355 | 53.8 | 1.6 | 20-31.6 | |

| 400 | 16 | 232 | 648 | 571.5 | 469.9 | 400 | 405 | 57.2 | 1.6 | 20-35 | |

| 450 | 18 | 264 | 713 | 628.6 | 533.4 | 450 | 455 | 60.5 | 1.6 | 24-35 | |

| 500 | 20 | 292 | 775 | 685.8 | 584.2 | 500 | 505 | 63.5 | 1.6 | 24-35 | |

| 600 | 24 | 318 | 914 | 812.8 | 692.2 | 600 | 608 | 69.9 | 1.6 | 24-41.1 | |

| 600LB | 50 | 2 | 60 | 165 | 127 | 92 | 51 | 58 | 25.4 | 6.4 | 8-19 |

| 65 | 2-1/2 | 67 | 190 | 149 | 105 | 65 | 73 | 29 | 6.4 | 8-22 | |

| 80 | 3 | 73 | 210 | 168 | 127 | 80 | 88 | 32 | 6.4 | 8-22 | |

| 100 | 4 | 79 | 273 | 216 | 157.2 | 102 | 108 | 38.5 | 6.4 | 8-25 | |

| 125 | 5 | 105 | 330 | 266.7 | 185.7 | 127 | 136 | 44.5 | 6.4 | 8-28.5 | |

| 150 | 6 | 136 | 356 | 292.1 | 215.9 | 152 | 162 | 47.8 | 6.4 | 12-28.5 | |

| 200 | 8 | 165 | 419 | 349.2 | 269.5 | 200 | 212 | 55.6 | 6.4 | 12-31.8 | |

| 250 | 10 | 213 | 508 | 431.8 | 323.8 | 250 | 266 | 63.5 | 6.4 | 16-35 | |

| 300 | 12 | 229 | 559 | 489 | 381 | 305 | 312 | 66.5 | 6.4 | 20-35 | |

| 350 | 14 | 273 | 603 | 527 | 412.8 | 337 | 355 | 69.9 | 6.4 | 20-38.1 | |

| 400 | 16 | 305 | 686 | 603.2 | 469.9 | 387 | 400 | 76.2 | 6.4 | 20-41.1 | |

| 450 | 18 | 362 | 743 | 654 | 533.4 | 438 | 450 | 82.6 | 6.4 | 20-44.5 | |

| 500 | 20 | 368 | 813 | 723.9 | 584.2 | 489 | 500 | 88.9 | 6.4 | 24-44.5 | |

| 600 | 24 | 438 | 940 | 838.2 | 692.2 | 591 | 600 | 101.6 | 6.4 | 24-50.8 | |