概述

B33系列高性能三片體球閥設(shè)計用于高壓,防火,執(zhí)行器連接靈活,循環(huán)壽命長,簡單現(xiàn)場維護(hù)等多項高性能服務(wù)。三片體設(shè)計使得維修方便,無需拆卸閥蓋。這種閥門的對焊、承插焊和螺紋很受歡迎。

特點

• 三片體外開式設(shè)計,便于現(xiàn)場維護(hù)全通徑和縮徑都可生產(chǎn)

• 精鑄閥體,無鑄造缺陷,表面細(xì)致

• 防脫出閥軸

• 聚四氟乙烯加25%碳纖維閥座標(biāo)準(zhǔn)適用于高壓力和高溫度,更耐磨損,可提供多種閥座和密封材料

• 球槽內(nèi)有減壓孔

• 符合ISO5211的安裝帶中心定位

• 用于球軸體的防靜電裝置

• 球形浮動閥桿帶來更高的循環(huán)壽命

• 可提供防火安全型

• 封裝的閥體密封允許在無需拆卸的情況下進(jìn)行焊接

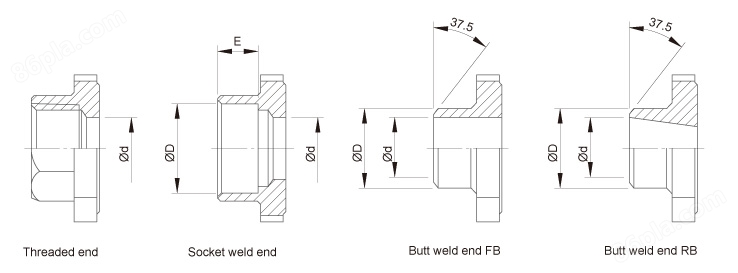

| 連接標(biāo)準(zhǔn) | 螺紋BSPP-ISO228/1 |

| 對焊-ISO1127, EN12627, SMS3008 | |

| 承插焊接 ANSI B16.11 | |

| 公稱直徑 | 全通徑 1/4"-2 1/2",縮徑 1/2" 至 2 1/2" |

| 壓力等級 | 2000PSI for 1/4"-1", 1500PSI for 1 1/4"-2 1/2" |

| 結(jié)構(gòu)長度 | 閥體孔心距及結(jié)構(gòu)長度適合worcester,Valtac and Mecafrance,因此閥體可安裝在現(xiàn)有連接間 |

| 溫度范圍 | -38°C ~ +250°C |

| 操作裝置 | 手柄、氣動頭、電動頭 |

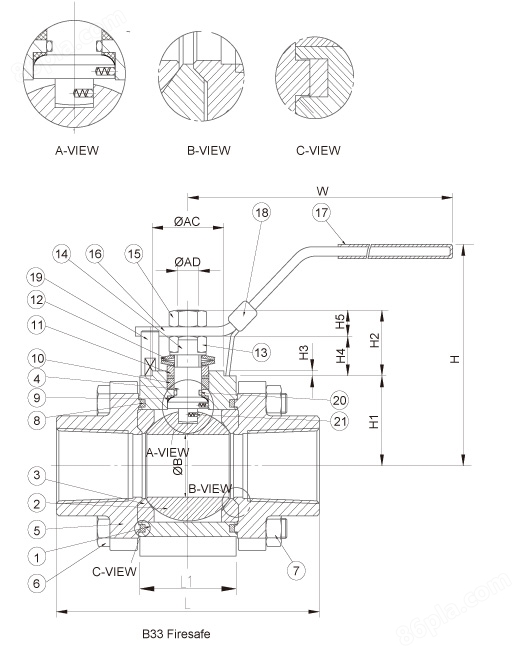

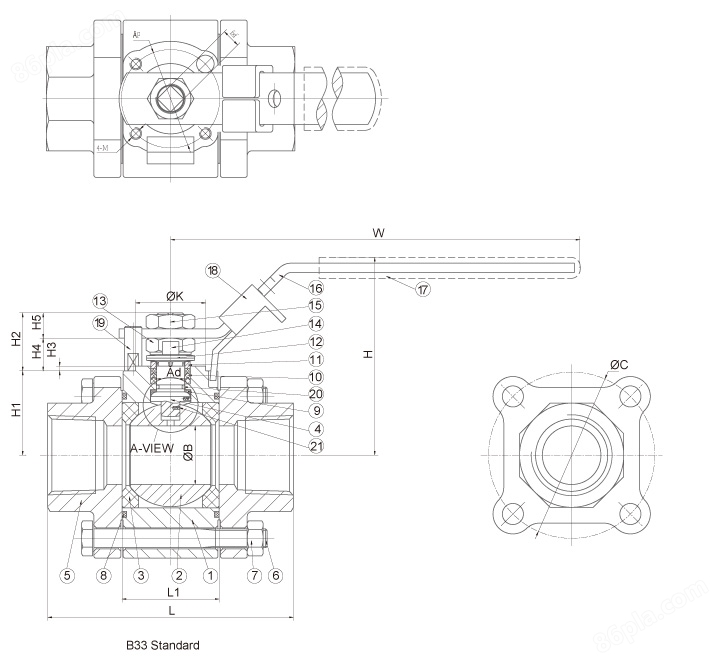

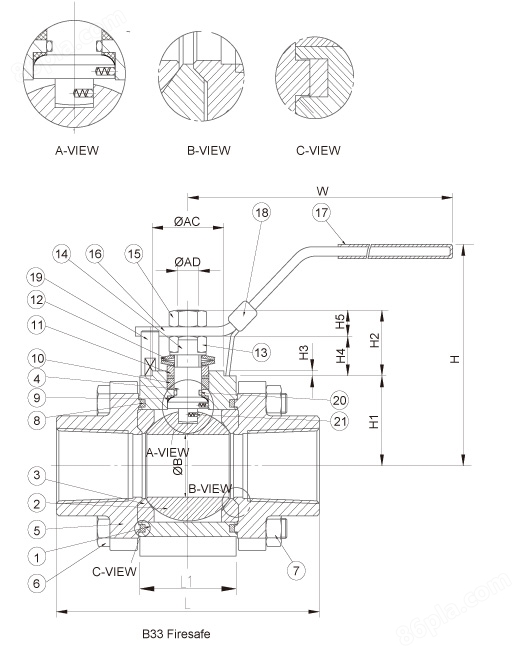

| 編號 | 零件名稱 | 材質(zhì) | |

| 1 | 閥體 | F316L | A105 |

| 2 | 閥球 | SS316L | SS304 |

| 3 | 閥座 | RPTFE | |

| 4 | 閥軸 | SS316L | SS304 |

| 5 | 閥蓋 | F316L | A105 |

| 6 | 螺栓 | SS304 | |

| 7 | 螺母 | SS304 | |

| 8 | 螺栓 | 標(biāo)準(zhǔn)PTFE,防火石墨 | |

| 9 | 止推墊圈 | RPTFE | |

| 10 | 填料 | 標(biāo)準(zhǔn)RPTFE,防火石墨 | |

| 11 | 密封壓蓋 | SS304 | |

| 12 | 碟簧 | SS304 | |

| 13 | 螺母 | SS304 | |

| 14 | 鎖緊墊圈 | SS304 | |

| 15 | 螺母 | SS304 | |

| 16 | 手柄 | SS304 | |

| 17 | 手柄套 | PVC | |

| 18 | 手柄鎖件 | SS304 | |

| 19 | 定位銷 | SS304 | |

| 20 | O型密封圈 | FPM | |

| 21 | 防靜電裝置 | SS316 | |

| 尺寸 | B | C | EN12627 | ISO1127 | SMS3008 | E | H | H1 | H2 | H3 | H4 | L | L1 | W | 安裝用法蘭 | 閥軸 | 重量(kg) | ||||||||

| DN | 英寸 | d | D | d | D | d | D | ISO5211 | F | M | K | f | H5 | ||||||||||||

| 8F | 1/4"F | 10 | 45.0 | 11.5 | 14.0 | 10.3 | 13.5 | 8.0 | 10.0 | 10 | 63 | 30 | 7.5 | 0.5 | 2 | 65 | 20.5 | 134 | F03 | 36 | M5 | 25 | 7 | 5.5 | 0.8 |

| 10F | 3/8"F | 10 | 45.0 | 12.6 | 17.2 | 14.0 | 17.2 | 10.0 | 12.0 | 10 | 63 | 30 | 7.5 | 0.5 | 2 | 65 | 20.5 | 134 | F03 | 36 | M5 | 25 | 7 | 5.5 | 0.8 |

| 15R | 1/2"R | 10 | 45.0 | 15.0 | 21.7 | 18.1 | 21.3 | 16.0 | 18.0 | 63 | 30 | 7.5 | 0.5 | 2 | 65 | 20.5 | 134 | F03 | 36 | M5 | 25 | 7 | 5.5 | 0.8 | |

| 15F | 1/2"F | 15 | 54.0 | 15.0 | 21.7 | 18.1 | 21.3 | 16.0 | 18.0 | 10 | 68 | 29 | 17 | 2 | 8.6 | 75 | 24.5 | 134 | F03 | 36 | M5 | 25 | 7 | 8.4 | 0.8 |

| 20R | 3/4"R | 15 | 54.0 | 20.5 | 27.2 | 23.7 | 26.9 | 22.6 | 25.0 | 68 | 29 | 17 | 2 | 8.6 | 75 | 24.5 | 134 | F03 | 36 | M5 | 25 | 7 | 8.4 | 0.9 | |

| 20F | 3/4"F | 20 | 62.5 | 20.5 | 27.2 | 23.7 | 26.9 | 22.6 | 25.0 | 13 | 72 | 33 | 18 | 2 | 8.6 | 90 | 31.5 | 134 | F03 | 36 | M5 | 25 | 7 | 9.2 | 1.3 |

| 25R | 1"R | 20 | 62.5 | 25.7 | 34.0 | 29.7 | 33.7 | 29.6 | 32.0 | 72 | 33 | 18 | 2 | 8.6 | 90 | 31.5 | 134 | F03 | 36 | M5 | 25 | 7 | 9.2 | 1.4 | |

| 25F | 1"F | 25 | 71.0 | 25.7 | 34.0 | 29.7 | 33.7 | 29.6 | 32.0 | 13 | 85 | 36 | 24 | 2 | 14 | 110 | 41.5 | 175 | F04 | 42 | M5 | 30 | 9 | 10.0 | 2.1 |

| 32R | 1 1/4"R | 25 | 71.0 | 34.4 | 42.7 | 38.4 | 42.4 | 31.3 | 33.7 | 85 | 36 | 24 | 2 | 14 | 110 | 41.5 | 175 | F04 | 42 | M5 | 30 | 9 | 10.0 | 2.2 | |

| 32F | 1 1/4"F | 32 | 80.0 | 34.4 | 42.7 | 38.4 | 42.4 | 31.3 | 33.7 | 13 | 89 | 40 | 24 | 2 | 14 | 115 | 48.5 | 175 | F04 | 42 | M5 | 30 | 9 | 10.0 | 2.6 |

| 40R | 1 1/2"R | 32 | 80.0 | 40.3 | 48.6 | 44.3 | 48.3 | 35.6 | 38.0 | 89 | 40 | 24 | 2 | 14 | 115 | 48.5 | 175 | F04 | 42 | M5 | 30 | 9 | 10.0 | 2.7 | |

| 40F | 1 1/2"F | 38 | 94.0 | 40.3 | 48.6 | 44.3 | 48.3 | 35.6 | 38.0 | 13 | 100 | 46.7 | 30 | 2.3 | 16 | 130 | 56.3 | 210 | F05 | 50 | M6 | 35 | 11 | 13.7 | 3.8 |

| 50R | 2"R | 38 | 94.0 | 51.3 | 60.5 | 55.1 | 60.3 | 48.6 | 51.0 | 100 | 46.7 | 30 | 2.3 | 16 | 130 | 56.3 | 210 | F05 | 50 | M6 | 35 | 11 | 13.7 | 4 | |

| 50F | 2"F | 50 | 112.5 | 51.3 | 60.5 | 55.1 | 60.3 | 48.6 | 51.0 | 16 | 118 | 69.5 | 25.5 | 1.5 | 11.6 | 145 | 71.5 | 210 | F05 | 50 | M6 | 35 | 11 | 13.9 | 5.5 |

| 65R | 2 1/2"R | 50 | 112.5 | 67.1 | 76.3 | 70.9 | 76.1 | 60.3 | 63.5 | 118 | 69.5 | 25.5 | 1.5 | 11.6 | 145 | 71.5 | 210 | F05 | 50 | M6 | 35 | 11 | 13.9 | 6.8 | |