| Model No.: | DEG-24P | Trademark: | DEGREE |

| Place of Origin: | Taizhou, China | Delivery Date: | 45-60 Days |

| Packing: | General Packing | Payment Type: | T/T & L/C |

| Certificates: | CE, ISO9001:2008 | Export Markets: | All World |

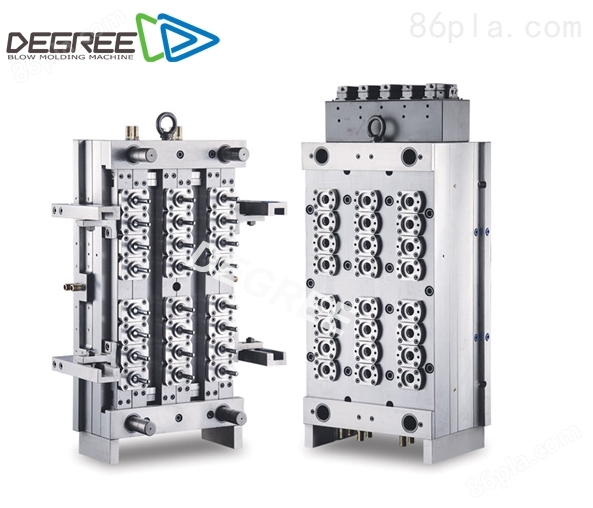

PET Preforms

Mold Features

1. Valve gate

pin-valve gate ,pneumatic drive the nozzle pin simultaneous high speed open and close action, which can effectively cool the injection hole open and close actions on each cavity. Reliable seal function, smooth moving, low thermal expansion rate, long using life and also saves electric energy

2. Hot runner

hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production, cavity with lower injection pressure to reduce wear and tear of mould parts

3. heat system

with double heating system, it has separate temperature cool mode ,the heat bar are used to heat hot-runner mainfold , small heaters supply the heating temperature for cavity nozzle continuously.

4. cooling system

each parts including core ,cavity and valve gate has independently cooling system.

5. heat treatment

mechanical treatment cavity and core to prolong service life ,nitrogen treatment with neck screw. with fitly operation ,guarantee Long using life over 2.0 million times of injection cycle.

Main Data

| Preform weight | 10gr-50gr |

| Neck size | 28-38mm |

| Mould cavity | 24 |

| Mould base material | P20 steel |

| Core/cavity material | Germany 2316 steel or Sweden S136 |

| Screw neck material | Germany 2316 steel or Sweden S136 |

| Mould size | Based on preform sample |

| Mould weight | About 2000kg |

| Heating plate | P20 steel |

| Pre-form type | Without injection tail, no need cutting |

| Mould structure | Automatic knockout, self-lock |

| Hot runner | Germany HOTSET |

| Heat insulation cap | USA DUPONT |

| Mould life time | 2000000 shot times |

| Mould warranty | 1years |

| Lead time | 45-60days |

| Packing terms | Standard export wooden box |